The vast majority of businesses require some sort of machinery to get the job done correctly. From major manufacturing operations that employ thousands of workers, to a self-owned custom cabinetry company, using machines is essential to an enormous array of work-related tasks.

As every business owner should know, the machines we use also pose a potential threat to the safety and wellbeing of our workers. It only takes one second of inattention or imprecision for machinery to cause serious bodily harm. Providing machine guarding safety is thus an elemental part of a safe workplace culture and environment.

Below, we take an in-depth look at the statistics behind machine-related injuries. We then offer a few suggestions for improving machine safety to limit worker injury and help your company avoid costly workers’ compensation payments.

Statistics on Machine-Related Injuries

Workplace injuries are caused by several different factors. Inadvertent slips and falls, inadequate signs and warnings in potentially hazardous areas, and even improper posture all are major causes of worker injuries that lead to missed work time, a drop in productivity, and higher medical costs for the employers.

However, machine-related injuries are generally much more severe in scope.

The Bureau of Labor Statistics (BLS) recently released a report stating that over 34,000 workers sustain a lost-time injury in the workplace every year due to machine-related accidents. Despite the frequency of machine-related workplace accidents, some employers continue to avoid implementing proper machine guarding.

The BLS report goes on to find that lack of machine safeguarding is one of the most commonly cited employee safety violations. There were at least 1,743 violations issued in 2019 alone for a lack of proper machine safety.

One expert in machine safeguarding and combustion safety solutions states that "our research has indicated that approximately half of all machine shops are still not guarded. Coupled with a lack of operator training, this creates a working environment that is high risk for both employees and employers."

Types of Machine Guards

There are several different types of guarding methods that are designed to protect employees and operators from potential injuries. These methods can be divided into barrier guards, two-hand tripping devices, and electronic safety devices. Depending on the type machinery your company uses, the actual type of machine guard might include:

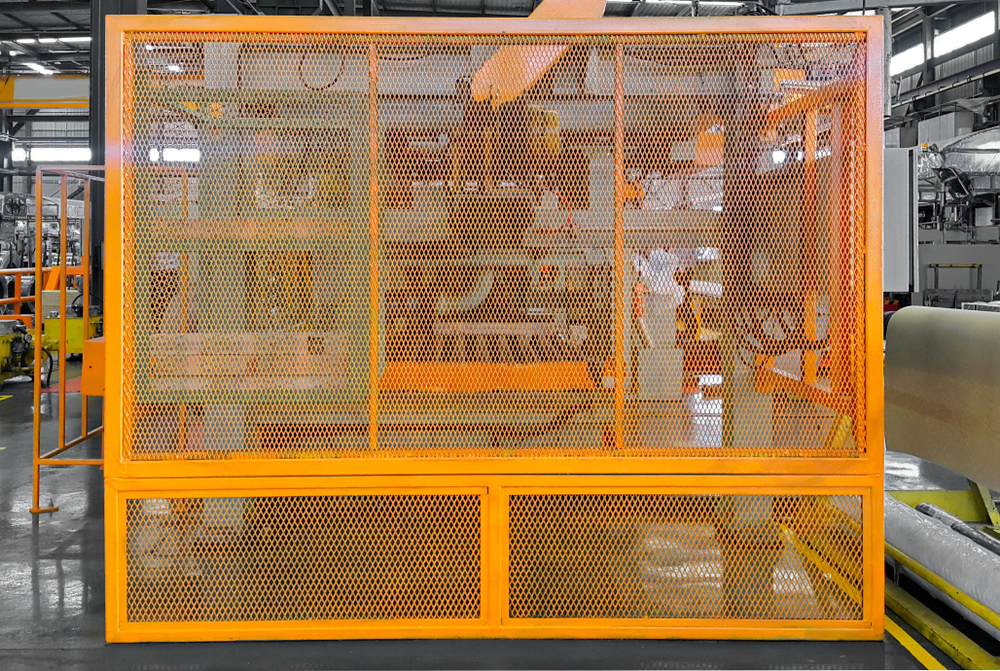

- Fixed guards. These machine guards provide a solid barrier or obstacle between the operator and the moving parts of the machine. Fixed guards can include gates, fences, railings, and physical covers for sharp blades, presses, or other moving parts that can cause injury.

- Interlocked guards. This type of machine guard is a type of device that disconnects the power source of the machine. When an interlocked guard is opened, removed, or touched, it essentially powers down the machine, and will not allow the machine to resume operation until the guard is reinserted.

- Adjustable guards. Many of the above types of machine guards can also be adjusted so that they offer protection for different sized operators or varying sizes of stock.

- Self-adjusting guards. Lastly, self-adjusting machine guards are designed to move on their own given the size or position of the workplace. These automatic guards protect workers when machinery is in operation.

In addition to the above-mentioned types of machine guards, there are also several “point-of-operation” machine guards that can be used by individual operators in a workplace setting.

Examples of tools that require point-of-operation machine guards include:

- Guillotine cutters

- Shears

- Alligator shears

- Power presses

- Milling machines

- Power saws

- Jointers

- Portable power tools

The type of mandatory machine guards will obviously depend on the type of business or industry. However, the Occupational Safety and Health Administration has machine guarding standards for businesses that operate in the agriculture, general industry, maritime, and construction industries. You can find those detailed standards here.

Guard Your Team With Work-Fit

If your business relies on heavy machinery with moving parts to get the job done, you might consider hiring specialists with experience in workplace injury management to properly design the machine guarding and operations training that your employees deserve. Work-Fit is a leading onsite injury prevention and management company for your workforce.

Our company has years of experience in helping businesses from all different industries to create and implement holistic injury prevention programs, via both on-site and telehealth/virtual services. Our trained professionals will tailor our services to your industry to help you find the most appropriate machine guarding technology.

Once you’ve ensured that your company is in compliance with OSHA regulations, you’ll simultaneously limit worker injuries while leading to savings on employer healthcare costs. Contact Work-Fit today to see how we can help your company develop the proper machine guarding to protect your workforce.